- [News]Vacuum Casting: Accelerating Innovation in the Automotive Industry with Mastars04 Nov,2025

- While technologies like 3D printing have revolutionized rapid prototyping, Vacuum Castingremains a cornerstone technology for producing high-quality, functional prototypes and small-batch components. This process is indispensable for bridging the gap between a digital design and mass production, especially within the automotive sector.

-

- [FAQ]What Is Vacuum Casting? Definition, methods, process, comparison31 Oct,2025

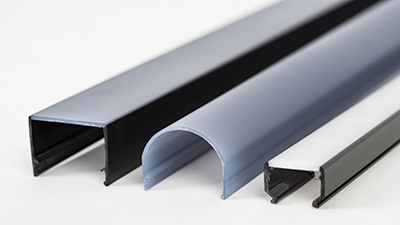

- Vacuum Casting, also known as Polyurethane (PU) Casting or Urethane Casting, is an advanced manufacturing process used to produce high-quality, functional prototypes and end-use parts in small to medium volumes (typically 10-50 parts, but up to 100+). It is renowned for replicating the properties of injection-molded plastics without the high cost and lead time of production-grade tooling.

-

- [FAQ]A detailed introduction to Rapid CNC Prototyping31 Oct,2025

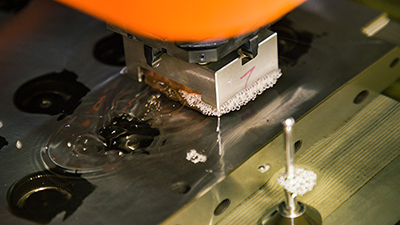

- Rapid CNC Machining refers to the use of Computer Numerical Control (CNC) machining technologies—specifically milling and turning—in an accelerated, highly efficient manner to produce functional prototypes, tooling components, and low-volume production parts in the shortest possible lead time.

-

- [Blog]CNC Machining in Medical Device Prototyping: A Guide30 Oct,2025

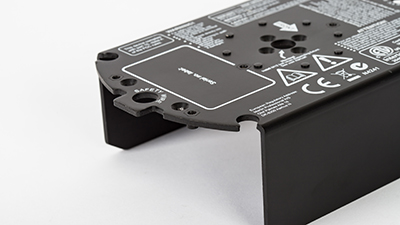

- CNC machining is a precise manufacturing process vital for creating medical device prototypes. It enables developers to produce components with tight tolerances using biocompatible materials like titanium, stainless steel, and PEEK. These p...

-

- [FAQ]Mastars: Detail Guide About Aluminum Injection Molding16 Mar,2022

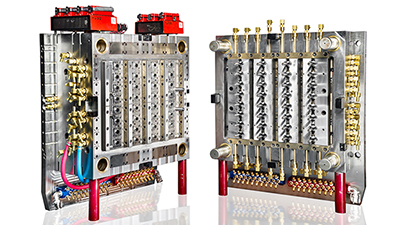

- Prototypes or real products are produced by the aluminum injection molding technique. The aluminum tooling technique is used for the process of aluminum injection molding. It is the process based on the injection molding technique. Mastars is also a metal prototype maker.

-

- [Blog]Advancements in Modular Prototyping Equipment24 Sep,2025

- Modular prototyping is transforming manufacturing by driving faster, cost-efficient product development. These systems use cutting-edge techniques like 3D printing, modular CNC machining, and AI-driven design tools to create prototypes dire...

-

- [Blog]Why OEMs Use 3D Printing for Low-Volume Production16 Sep,2025

- Why OEMs Use 3D Printing for Low-Volume Production | Mastars Lower Tooling Costs Faster Lead Times Traditional methods like injection molding require expensive tooling and molds. For small batches or prototypes, the tooling cost alone can ...

-

- [FAQ]Full Guide for Selecting the Right CNC Material|Mastars26 Feb,2022

- You must know that CNC technology is highly repeatable and accurate and offers a better manufacturing process for the production of parts and prototypes. Also, this uses a subtractive procedure that cuts material with computer-controlled tools. As a result, you will always get a professional quality product.

-

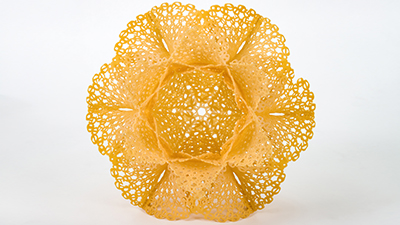

- [Blog]Vacuum Casting for Prototyping: Design Guide29 Aug,2025

- Vacuum casting is a fast and cost-effective way to produce high-quality prototypes, especially for small to medium production runs (5–50 units). Using silicone moulds and polyurethane resins, this method replicates intricate designs w...

-