Mastars is one of the toppest companies in the world which offer sheet metal prototyping services. Fitted with the latest cutting edge technology, we are ready and equipped for nearly any task required by our customers. Whether you are looking for production intent sheet metal parts or one-off, mock-up style for fit & function, Mastars is your one-stop shop for prototypes, assemblies and short-run services. Our team of highly skilled toolmakers, designers and technicians work seamlessly to provide the highest level of quality. With each piece, we assess for precise tolerances and requirements that challenge the best in the industry.

We offer our services and expertise to a number of industries > Automotive > Aerospace > Appliance > Agricultural > Medical > Recreational > Military > Industrial 01

We offer our services and expertise to a number of industries > Automotive > Aerospace > Appliance > Agricultural > Medical > Recreational > Military > Industrial 01

To better satisfy our customer’s beeds, our capabilities> sheet metal stamping and forming > 5-Axis Laser cutting > 3-Axis laser cutting > Manual TIG welding > Manual MIG welding > FEA based flat blank development > Full-Service CNC machining > CMM Layouts 02

To better satisfy our customer’s beeds, our capabilities> sheet metal stamping and forming > 5-Axis Laser cutting > 3-Axis laser cutting > Manual TIG welding > Manual MIG welding > FEA based flat blank development > Full-Service CNC machining > CMM Layouts 02

blanking ---- bending, stretching ---- riveting, drilling, tapping, flanging, welding ---- surface treatment

1. Cold-rolled sheet SPCC: mainly used for electroplating and baking finish parts, low cost, easy to form, material thickness ≤ 3.2mm.

2. Hot-rolled sheet SHCC: material thickness ≥3.0mm, it is also used for electroplating, paint parts, low cost, but it’s difficult to form, mainly used for flat parts.

3. Galvanized sheet SECC, SGCC. The SECC electrolytic plate is divided into N material and P material. The N material is mainly used for parts without surface treatment, and the cost is high. The P material is used for spraying parts.

4. Copper: it is mainly used for electrical conductivity, and its surface treatment is nickel plating, chromium plating, or not treated, and the cost is high.

5. Aluminum plate: generally use surface chromate (J11-A) oxidation (conductive oxidation, chemical oxidation), high cost, silver plating, nickel plating.

6. Aluminum profiles: a material with a complex cross-sectional structure, which is widely used in various sub-boxes. The surface treatment is the same as that of the aluminum plate.

7. Stainless steel: it is mainly without any surface treatment, and the cost is high.

Fiber laser cutting machine> Swiss Bystronic laser power: 6000-12000w > Processing width (length × width): 12000 × 3200mm > Plane cutting thickness: stainless steel plate, carbon steel plate, aluminum plate and other metal plates 0.5-50mm > Long-term batch stable cutting of medium and thick plates with a thickness of more than 20mm, and ultra-thick plates with a maximum thickness of more than 50mm. The length can be customized according to the user's processing needs. The processing materials are wide, which can process both plates and large-sized sections.

Fiber laser cutting machine> Swiss Bystronic laser power: 6000-12000w > Processing width (length × width): 12000 × 3200mm > Plane cutting thickness: stainless steel plate, carbon steel plate, aluminum plate and other metal plates 0.5-50mm > Long-term batch stable cutting of medium and thick plates with a thickness of more than 20mm, and ultra-thick plates with a maximum thickness of more than 50mm. The length can be customized according to the user's processing needs. The processing materials are wide, which can process both plates and large-sized sections.

CNC bending machines Including AIGENI large CNC bending machine AG-1030 > Pressure: 100T > Processing range: 3000mm > Machining accuracy: ±30′ > Clamping: Quick Clamping

CNC bending machines Including AIGENI large CNC bending machine AG-1030 > Pressure: 100T > Processing range: 3000mm > Machining accuracy: ±30′ > Clamping: Quick Clamping

Punching machinesThere are 22 sets of Goanwin and Kinglan punching machines, with a pressure range of 60T-500T. Including Kinglan ALE-500 closed double crankshaft high-precision steel frame punch: > Punch capacity: 500T > Maximum die height: 600mm > Slider stroke: 300mm

Punching machinesThere are 22 sets of Goanwin and Kinglan punching machines, with a pressure range of 60T-500T. Including Kinglan ALE-500 closed double crankshaft high-precision steel frame punch: > Punch capacity: 500T > Maximum die height: 600mm > Slider stroke: 300mm

Other machines Riveting machine, argon arc welding machine, automatic stamping manipulator, universal radial drilling machine, universal radial milling machine, grinding machine, slow wire, medium wire, fast wire and other equipment are readily available, providing full-process production services.

Other machines Riveting machine, argon arc welding machine, automatic stamping manipulator, universal radial drilling machine, universal radial milling machine, grinding machine, slow wire, medium wire, fast wire and other equipment are readily available, providing full-process production services.

High-quality raw materials

The machining materials we use are stainless steel, aluminum, non-ferrous metals and some alloys. Adequate and abundant supply of raw materials can fully meet the raw material needs of customers, and prepare materials at a fast speed, which not only guarantees quality but also saves time.

Custom Experience

More than ten years of industry customization experience, sheet metal processing of non- standard precision structural parts, and rapid prototyping of large structural parts allow us to easily respond to various production requirements in multiple fields, produce more complex and high-precision sheet metal products, and provide professional advice on raw material selection, design and production for customers.

Pursuit of quality

In the production process of the product, we ensure the machining accuracy of the workpiece through advanced equipment, and the rich experience of the operator strictly controls the production quality.

Our testing center has advanced comprehensive testing equipment, such as German GOM ATOS TRIPLE Sacn III Blue ray 3D scanner, Swedish Hexagon CMM, 2.5-dimensional automatic image measuring instrument, Hitachi handheld X-ray fluorescence spectrometer, Switzerland TESA Height meter, Japan Mitohiro Roughness Meter, etc. All this ensure that your products meet the design and functional requirements.

Surface treatment technology

We can provide surface treatment services to meet the special requirements of customers. At present, we can provide powder spraying, sandblasting, polishing, electroplating (gold plating, silver plating, nickel plating, tin plating, zinc plating, etc.), anodizing, electrophoresis and other surfaces treatment services.

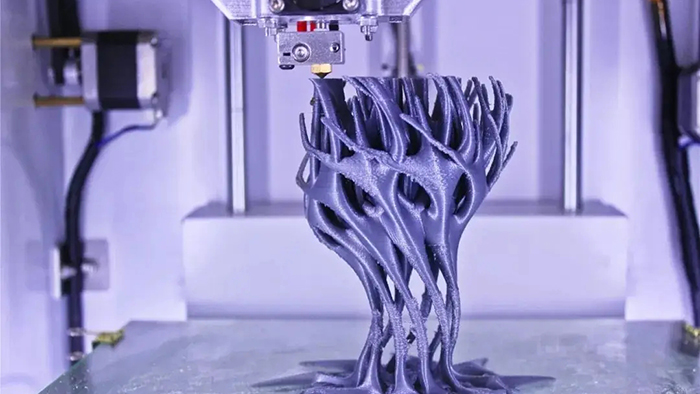

Hybrid Prototyping: CNC and 3D Printing

Hybrid Prototyping: CNC and 3D Printing

Top 7 Surface Finishes for Prototyping

Top 7 Surface Finishes for Prototyping

Rapid Prototyping for the Automotive Industry From Concept to Prototype in Days

Rapid Prototyping for the Automotive Industry From Concept to Prototype in Days

3D printing post-treatment process introduction |3D printing rapid prototyping

3D printing post-treatment process introduction |3D printing rapid prototyping