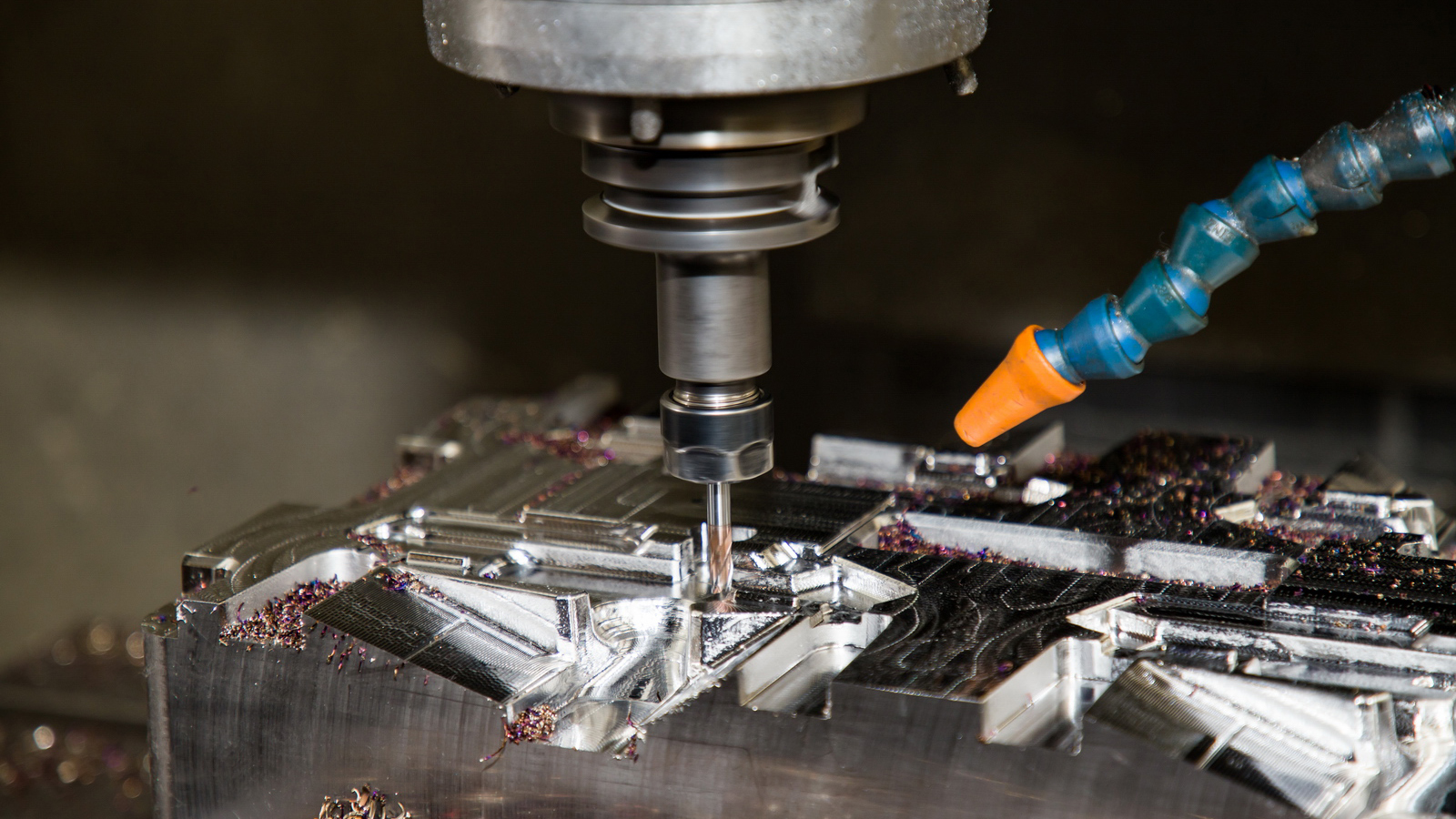

Mastars has more than 20 years of professional forging experience, focusing on hot forging, warm forging, cold forging, 3D forging technology for non-ferrous metals such as copper, aluminum alloy, stainless steel, etc., and has one-stop customized service of mold development, mold manufacturing, product manufacturing and surface treatment. Supporting large-scale equipment: 4000 tons, 2500 tons, 800 tons, 630 tons, 400 tons forging machines, 1000 tons 4D forging machines, 500 tons 3D forging machines, CNC machining centers, punches, spark machines, electric discharge machines, grinders, etc. Perfect equipment and strong technical force have unique advantages in the development and manufacture of "high, precise and large" forgings.

Mastars has more than 20 years of professional forging experience, focusing on hot forging, warm forging, cold forging, 3D forging technology for non-ferrous metals such as copper, aluminum alloy, stainless steel, etc., and has one-stop customized service of mold development, mold manufacturing, product manufacturing and surface treatment. Supporting large-scale equipment: 4000 tons, 2500 tons, 800 tons, 630 tons, 400 tons forging machines, 1000 tons 4D forging machines, 500 tons 3D forging machines, CNC machining centers, punches, spark machines, electric discharge machines, grinders, etc. Perfect equipment and strong technical force have unique advantages in the development and manufacture of "high, precise and large" forgings.

Products are widely used in automobiles, electric vehicles, motorcycles, bicycles, outdoor sports, military ships, aerospace and other industries. Forging equipment with a tonnage of 4000 tons can forge workpieces with an outer diameter of 500mm and a length of 1000mm. The forging precision can reach 0.1--0.2mm, and the machining dimensional accuracy tolerance is 0.01-0.05mm.

Products are widely used in automobiles, electric vehicles, motorcycles, bicycles, outdoor sports, military ships, aerospace and other industries. Forging equipment with a tonnage of 4000 tons can forge workpieces with an outer diameter of 500mm and a length of 1000mm. The forging precision can reach 0.1--0.2mm, and the machining dimensional accuracy tolerance is 0.01-0.05mm.

| Material | Aluminum Alloy AL6061 | Material technology | forging |

| Forging precision | 0.05mm | Processing technology | CNC machining |

| CNC precision | 0.02mm | Mold core material | imported SKD61 die steel |

| Mold core hardness | 48-52HRC | Mold life | 215,000 mold times |

| Mold cavity | one mold, one cavity | The daily production capacity of a single group of molds | 512pcs |

| Appearance process | vibration grinding, machining, polishing, oxidation | Number of forging die parting surfaces | upper and lower dies |

| Forging die installation method | upper and lower fixed forging die | Quality system | ISO9001 |

| Quality inspection frequency | AQL=0.5 | Scope of application | motorcycles, electric bicycles |

| Main processing equipment | blanking machine, intermediate frequency furnace, forging machine, punching machine, high temperature furnace, vibrating pot, CNC computer gong, polishing machine and tapping machine | ||

| Process flow | blanking + heating + rough forging embryo + fine forging embryo + trimming + T4T6 heat treatment + vibration grinding + CNC + polishing + oxidation | ||

| Material | Aluminum Alloy AL6061 | Material technology | forging |

| Forging precision | 0.05mm | Processing technology | CNC machining |

| CNC precision | 0.02mm | Mold core material | imported SKD61 die steel |

| Mold core hardness | 48-52HRC | Mold life | 215,000 mold times |

| Mold cavity | one mold, one cavity | The daily production capacity of a single group of molds | 512pcs |

| Appearance process | vibration grinding, machining, polishing, oxidation | Number of forging die parting surfaces | upper and lower dies |

| Forging die installation method | upper and lower fixed forging die | Quality system | ISO9001 |

| Quality inspection frequency | AQL=0.5 | Scope of application | motorcycles |

| Main processing equipment | blanking machine, intermediate frequency furnace, forging machine, punching machine, high temperature furnace, vibrating pot, CNC computer gong, polishing machine and tapping machine | ||

| Process flow | blanking + heating + rough forging embryo + fine forging embryo + trimming + T4T6 heat treatment + vibration grinding + CNC + polishing + oxidation | ||

| Material | Aluminum Alloy AL6061 | Material technology | forging |

| Forging precision | 0.05mm | Processing technology | CNC machining |

| CNC precision | 0.02mm | Mold core material | imported SKD61 die steel |

| Mold core hardness | 48-52HRC | Mold life | 215,000 mold times |

| Mold cavity | one mold, one cavity | The daily production capacity of a single group of molds | 512pcs |

| Appearance process | vibration grinding, machining, polishing, oxidation | Number of forging die parting surfaces | upper and lower dies |

| Forging die installation method | upper and lower fixed forging die | Quality system | ISO9001 |

| Quality inspection frequency | AQL=0.5 | Scope of application | motorcycles |

| Main processing equipment | blanking machine, intermediate frequency furnace, forging machine, punching machine, high temperature furnace, vibrating pot, CNC computer gong, polishing machine and tapping machine | ||

| Process flow | blanking + heating + rough forging embryo + fine forging embryo + trimming + T4T6 heat treatment + vibration grinding + CNC + polishing + oxidation | ||

| Material | Aluminum Alloy AL6061 | Material technology | forging |

| Forging precision | 0.05mm | Processing technology | CNC machining |

| CNC precision | 0.02mm | Mold core material | imported SKD61 die steel |

| Mold core hardness | 48-52HRC | Mold life | 215,000 mold times |

| Mold cavity | one mold, one cavity | The daily production capacity of a single group of molds | 512pcs |

| Appearance process | vibration grinding, machining, polishing, oxidation | Number of forging die parting surfaces | upper and lower dies |

| Forging die installation method | upper and lower fixed forging die | Quality system | ISO9001 |

| Quality inspection frequency | AQL=0.5 | Scope of application | electric bicycles |

| Main processing equipment | blanking machine, intermediate frequency furnace, forging machine, punching machine, high temperature furnace, vibrating pot, CNC computer gong, polishing machine and tapping machine | ||

| Process flow | blanking + heating + rough forging embryo + fine forging embryo + trimming + T4T6 heat treatment + vibration grinding + CNC + polishing + oxidation | ||

| Material | Aluminum Alloy AL6061 | Material technology | forging |

| Forging precision | 0.05mm | Processing technology | CNC machining |

| CNC precision | 0.02mm | Mold core material | imported SKD61 die steel |

| Mold core hardness | 48-52HRC | Mold life | 215,000 mold times |

| Mold cavity | one mold, one cavity | The daily production capacity of a single group of molds | 512pcs |

| Appearance process | vibration grinding, machining, polishing, oxidation | Number of forging die parting surfaces | upper and lower dies |

| Forging die installation method | upper and lower fixed forging die | Quality system | ISO9001 |

| Quality inspection frequency | AQL=0.5 | Scope of application | electric bicycles |

| Main processing equipment | blanking machine, intermediate frequency furnace, forging machine, punching machine, high temperature furnace, vibrating pot, CNC computer gong, polishing machine and tapping machine | ||

| Process flow | blanking + heating + rough forging embryo + fine forging embryo + trimming + T4T6 heat treatment + vibration grinding + CNC + polishing + oxidation | ||

| Material | Aluminum Alloy AL6061 | Material technology | forging |

| Forging precision | 0.05mm | Processing technology | CNC machining |

| CNC precision | 0.02mm | Mold core material | imported SKD61 die steel |

| Mold core hardness | 48-52HRC | Mold life | 215,000 mold times |

| Mold cavity | one mold, one cavity | The daily production capacity of a single group of molds | 512pcs |

| Appearance process | vibration grinding, machining, polishing, oxidation | Number of forging die parting surfaces | upper and lower dies |

| Forging die installation method | upper and lower fixed forging die | Quality system | ISO9001 |

| Quality inspection frequency | AQL=0.5 | Scope of application | motorcycles |

| Main processing equipment | blanking machine, intermediate frequency furnace, forging machine, punching machine, high temperature furnace, vibrating pot, CNC computer gong, polishing machine and tapping machine | ||

| Process flow | blanking + heating + rough forging embryo + fine forging embryo + trimming + T4T6 heat treatment + vibration grinding + CNC + polishing + oxidation | ||

| Material | Aluminum Alloy AL6061 | Material technology | forging |

| Forging precision | 0.05mm | Processing technology | CNC machining |

| CNC precision | 0.02mm | Mold core material | imported SKD61 die steel |

| Mold core hardness | 48-52HRC | Mold life | 215,000 mold times |

| Mold cavity | one mold, one cavity | The daily production capacity of a single group of molds | 512pcs |

| Appearance process | vibration grinding, machining, polishing, oxidation | Number of forging die parting surfaces | upper and lower dies |

| Forging die installation method | upper and lower fixed forging die | Quality system | ISO9001 |

| Quality inspection frequency | AQL=0.5 | Scope of application | motorcycles |

| Main processing equipment | blanking machine, intermediate frequency furnace, forging machine, punching machine, high temperature furnace, vibrating pot, CNC computer gong, polishing machine and tapping machine | ||

| Process flow | blanking + heating + rough forging embryo + fine forging embryo + trimming + T4T6 heat treatment + vibration grinding + CNC + polishing + oxidation | ||

| Material | Aluminum Alloy AL6061 | Material technology | forging |

| Forging precision | 0.05mm | Processing technology | CNC machining |

| CNC precision | 0.02mm | Mold core material | imported SKD61 die steel |

| Mold core hardness | 48-52HRC | Mold life | 215,000 mold times |

| Mold cavity | one mold, one cavity | The daily production capacity of a single group of molds | 420pcs |

| Appearance process | vibration grinding, machining, polishing, oxidation | Number of forging die parting surfaces | upper and lower dies |

| Forging die installation method | upper and lower fixed forging die | Quality system | ISO9001 |

| Quality inspection frequency | AQL=0.5 | Scope of application | motorcycles |

| Main processing equipment | blanking machine, intermediate frequency furnace, forging machine, punching machine, high temperature furnace, vibrating pot, CNC computer gong, polishing machine and tapping machine | ||

| Process flow | blanking + heating + rough forging embryo + fine forging embryo + trimming + T4T6 heat treatment + vibration grinding + CNC + polishing + oxidation | ||

| Material | Aluminum Alloy AL6061 | Material technology | forging |

| Forging precision | 0.05mm | Processing technology | CNC machining |

| CNC precision | 0.02mm | Mold core material | imported SKD61 die steel |

| Mold core hardness | 48-52HRC | Mold life | 215,000 mold times |

| Mold cavity | one mold, one cavity | The daily production capacity of a single group of molds | 450pcs |

| Appearance process | vibration grinding, machining, polishing, oxidation | Number of forging die parting surfaces | upper and lower dies |

| Forging die installation method | upper and lower fixed forging die | Quality system | ISO9001 |

| Quality inspection frequency | AQL=0.5 | Scope of application | motorcycles, electric bicycles |

| Main processing equipment | blanking machine, intermediate frequency furnace, forging machine, punching machine, high temperature furnace, vibrating pot, CNC computer gong, polishing machine and tapping machine | ||

| Process flow | blanking + heating + rough forging embryo + fine forging embryo + trimming + T4T6 heat treatment + vibration grinding + CNC + polishing + oxidation | ||

What are the CNC machining methods?|rapid cnc machining

What are the CNC machining methods?|rapid cnc machining

Tooling Tolerances in CNC Machining

Tooling Tolerances in CNC Machining

Mastars' “Rapid Response, Collaborative Communication” Workshop

Mastars' “Rapid Response, Collaborative Communication” Workshop

Digital Documentation for CNC Machining

Digital Documentation for CNC Machining