What is Vacuum Forming?

Mastars usesVarious leading technologies to make prototyping and functional parts, providing customers with rapid prototyping services

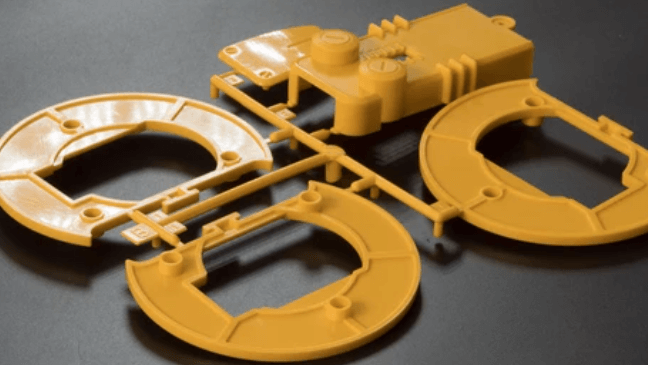

1、 What is vacuum forming?

Vacuum molding refers to making silica gel mold under vacuum by using the original template, and pouring with PU, silica gel, nylon, ABS and other materials under vacuum, so as to clone the same replica as the original template.

2、 Advantages of vacuum forming

1. Low cost, short production cycle, less waste, and much lower processing cost than CNC processing and 3D printing.

2. It is applicable to the processing and production of small batch products. After making an original, it can be copied according to the original.

3. Good molding operability. The cured soft molds are transparent or translucent, with good tensile strength, which is convenient for cutting and typing.

4. The probability of processing failure is small. As long as there is no problem with the original, the copy will not make mistakes.

5. Good repeatability. The silica gel used for molding has good fluidity before curing. Combined with vacuum defoaming, it can accurately maintain the detailed structure and decoration of the model.

3、 Disadvantages of vacuum forming prototype

1. The original sample of the product is required before vacuum forming can be carried out. The original sample here can be provided by the customer or the prototype processed by CNC according to the customer's needs;

2. Whether the product wall shrinks due to vacuum forming and whether the product needs to be formed;

3. Prototypes cannot be produced in large quantities, and the cost of single products is relatively high.

4. It is easy to shrink and deform, because it will shrink after high temperature heating and cooling, resulting in deformation. The general error is about 0.2mm. Other causes of shrinkage deformation are as follows:

1) Silica gel quality problem. When making silica gel mold, the quality of silica gel used in the mold is poor. The shrinkage rate of high-grade mold glue is 0.1%, that of ordinary mold glue is about 3%, and that of low-grade mold glue is higher.

2) Material shrinkage. The vacuum / low-pressure pouring prototype needs a very high temperature to make the plastic particles into a molten state during injection. Due to the influence of thermal expansion and cold shrinkage, the material may have just the right size at the time of pouring. Once it cools down, shrinkage / warpage will occur, which makes the product precision not up to the standard.

3) The workbench is uneven. The workbench for placing silica gel mold for vacuum filling is inclined. If you want to make a good vacuum forming prototype, the workbench where the silica gel mold is placed must be stable. It is convenient for the material to be poured evenly.

4) Insufficient fixation. The mold silica gel was not fully cured before it was put into use. Although the mold can generally be taken out within a few hours after pouring, it usually takes more than a week for the mold glue to fully solidify. If time is sufficient, it is best to take out the mold after pouring for a month and then start using it. However, now we pursue high efficiency and high quality, so it is unrealistic to use it after placing it for a long time.

Mastars is a prototype company in China. With our own factory, we adopt mature prototyping technologies (rapid CNC machining, rapid sheet metal prototyping, vacuum casting prototyping, 3D printing prototyping etc.), take new concepts or designs and bring them to life.

Mastars Industries CO., LTD

www.mastars.com

Email: marketing@mastars.com

Tel: +86 755-88210689

Fax: +86 755-8821 0685

Add: Building 6,Blue Sky Industrial Park, Ditang Road, Shajing Town, Shenzhen City, Guangdong, China