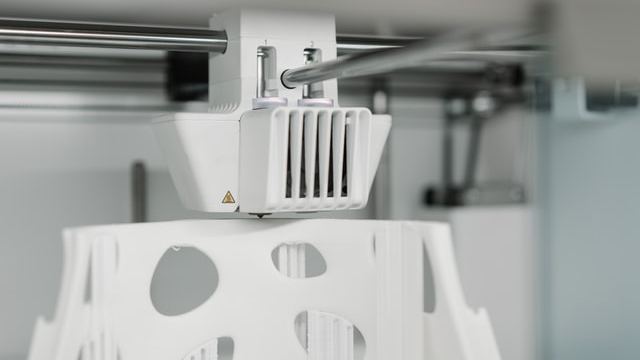

Mastars' rapid prototyping service can provide various prototyping services according to customers' needs, verify your designed, provide fast, efficient and cost-effective services, and lay the foundation for future mass production of your products. Let's look at the structural prototype and the appearance prototype.

What is the meaning of structural prototype proofing and what is the difference between structural prototype and appearance prototype? Structural prototypes are generally used for real test functions, while appearance prototypes are generally used for graduation design or exhibition.

Structural prototypes are movable prototypes with basic functions, such as car models. Structural prototypes must have wheels, doors, underbody, body and frame. As long as they are in appearance, they must be assembled with loose parts and can move like real cars in the market. Unstructured prototypes are also called appearance boards, which only look at the appearance and do not need to be moved.

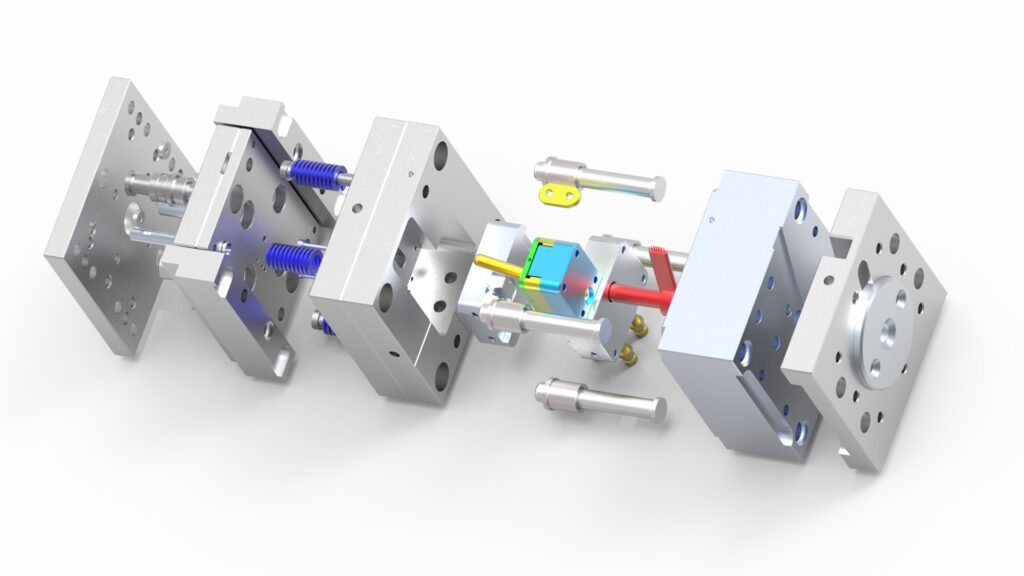

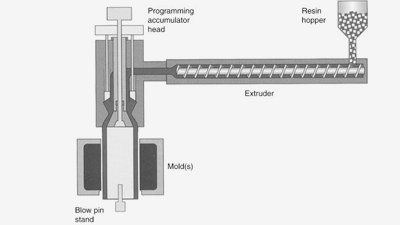

Prototype is the first step to verify the feasibility of the product. It is the most direct and effective way to find out the defects, deficiencies and disadvantages of the designed product, so as to improve the defects. Small batch trial production is usually needed to find out the deficiencies. The newly designed products generally cannot be guaranteed to be 100% intact. Once there are defects in direct mold opening production, they will be scrapped, which greatly wastes manpower, material resources and money; The prototype is generally a small number of samples, with short production cycle and less loss of human and material resources. It can quickly find out the shortcomings of product design, so as to improve and provide sufficient guarantee for mass production of products.

The structural prototype is simply that there is a structure inside the prototype, which is mainly used to verify whether the structural design is reasonable. It can be used to install electronic parts and can be used and sold as finished products; Generally speaking, the purpose of customer prototyping is to verify the appearance, structure and size of new products and see whether there are deficiencies in the design of products; It can also reduce the risk of product mold opening.

Structural prototype proofing can not only improve the work efficiency of the R & D and design department, but also meet the verification of some structure and performance in the process of product R & D, so as to reduce the development cost and time cost of products.

Mastars Industries CO., LTD

www.mastars.com

Email: marketing@mastars.com

Tel: +86 755-88210690

Mobile: +86 181 0029 4997

Add: Building 6,Blue Sky Industrial Park, Ditang Road, Shajing Town, Shenzhen City, Guangdong, China