What is rapid prototyping technology manufacturing

With the formation of global market integration, the competition in the manufacturing industry is fierce, and the speed of product development has increasingly become the main contradiction of competition. In this case, the ability to automate rapid product development (rapid design and rapid tooling), that is, rapid prototyping services, has become the strength of the global competition for manufacturing. At the same time, in order to meet the ever-changing user needs, the manufacturing industry also requires strong flexibility in manufacturing technology, which can be produced in small batches or even in one piece without increasing the cost of the product. Therefore, the speed of product development and the flexibility of manufacturing technology become critical.

In this social context, Rapid Prototyping Manufacturing Technology (RPM) was born in the United States in the late 1980s and quickly expanded to Japan and Europe. It is a major breakthrough in manufacturing technology in recent years.

Principle of rapid prototyping manufacturing

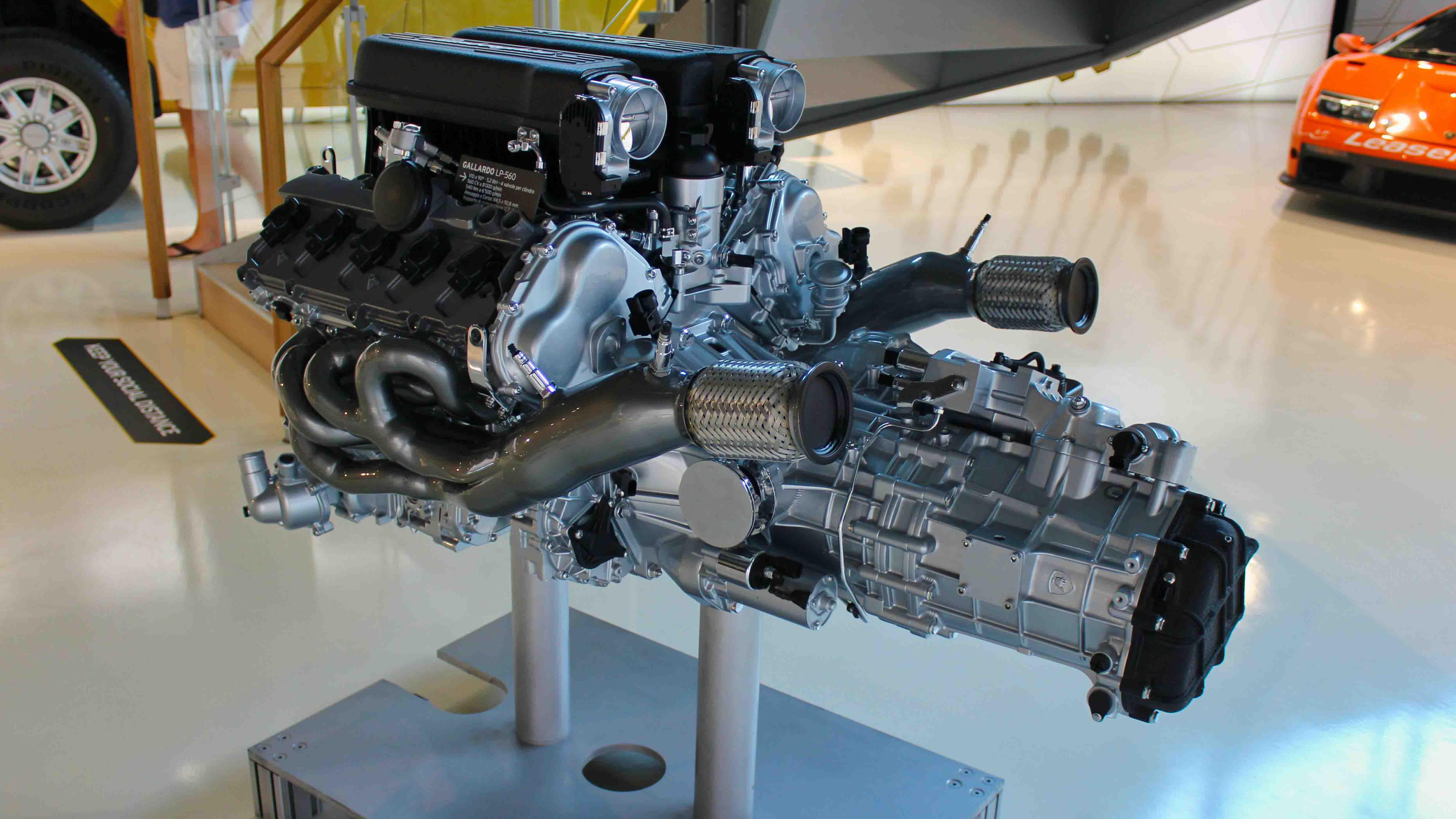

Rapid prototyping manufacturing technology is a comprehensive technology integrating material forming, CAD, numerical control, laser and other technologies. It is a system technology that integrates from part design to 3D solid prototype manufacturing.

The basic principle of rapid prototyping manufacturing technology is to stack (or stack) materials according to the hierarchical data of 3D CAD models without any molds, tools and tooling, and quickly produce prototypes of arbitrary complexity or A digital forming technique for parts. Rapid prototyping technology.

Features of rapid prototyping manufacturing

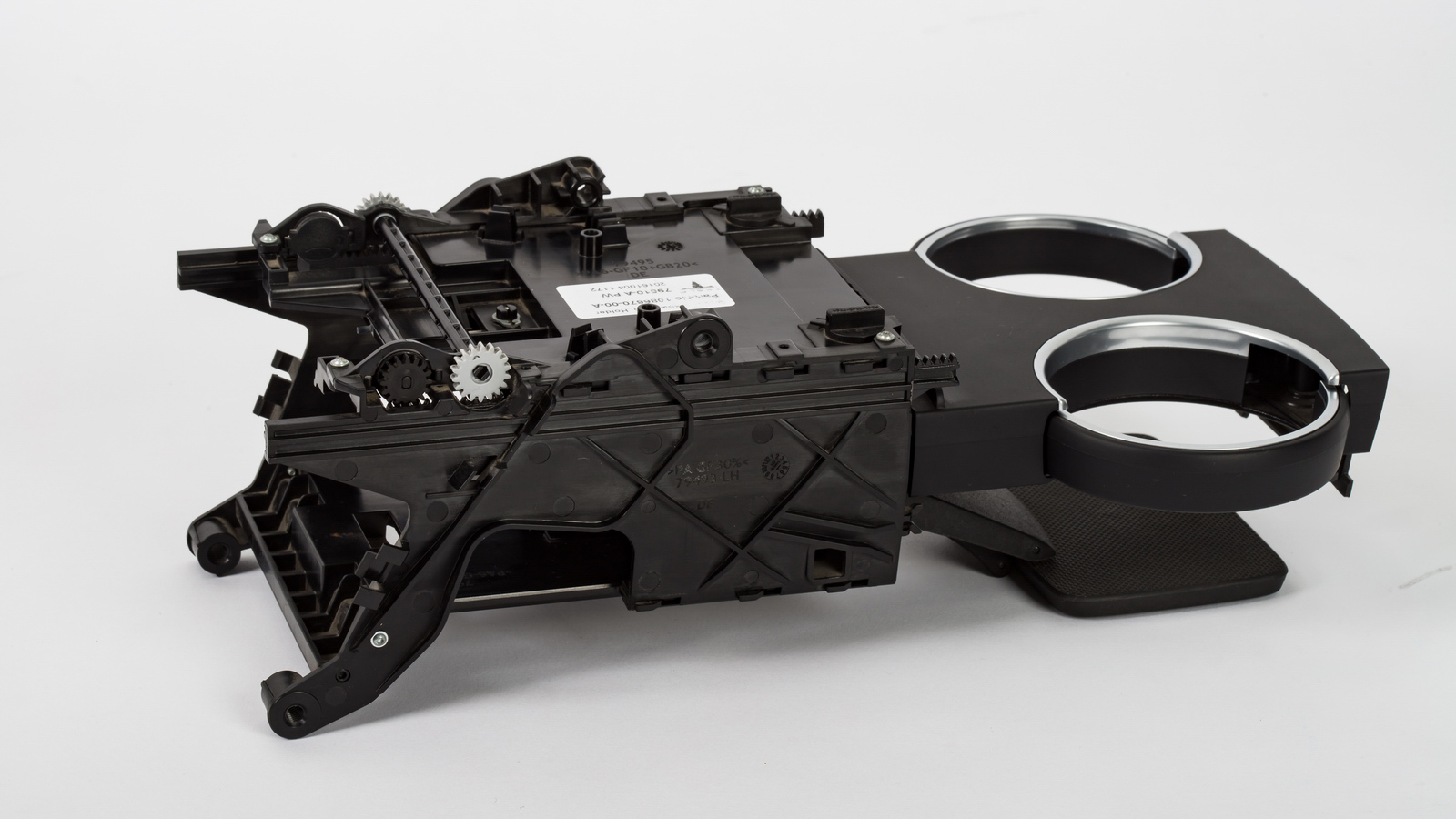

1) Freeform manufacturing

The meaning of free-form manufacturing has two aspects: one is that there is no need to use a tool to make a prototype or a part, thereby greatly shortening the trial production cycle of the new product and saving the cost of the mold; second, it is not subject to the complexity of the shape. Restricted, it is possible to make prototypes or parts of any shape and structure, and different materials.

2) Fast manufacturing efficiency

From the data obtained by CAD digital model or entity reverse to the original shape, it usually takes only a few hours or ten hours, and the speed is much faster than the traditional molding processing method.

3) Directly driven by the CAD model

Regardless of the rapid prototyping manufacturing process, the rapid prototyping manufacturing equipment system is directly or indirectly driven by a CAD digital model. The characteristics of rapid prototyping for rapid and free forming are determined.

4) The technology is highly integrated

The high integration of new materials, laser application technology, precision servo drive technology, computer technology and numerical control technology together support the realization of rapid prototyping technology.

5) High economic efficiency

Rapid prototyping technology creates prototypes or parts without the need for tooling, and is not related to the complexity of the forming or part, and the cost of the prototype or part itself is significantly reduced. In addition, due to the rapid prototyping technology in design visualization, appearance evaluation, assembly and functional inspection, and the function of the fast model master, it can significantly shorten the product development trial cycle and bring significant time benefits.

6) The accuracy is not as good as traditional processing

When the data model is layered, some data loss is inevitable and the layered manufacturing will inevitably produce step error. The phase transformation of the stacked forming and the internal stress generated by the solidification process will also cause warping deformation, which fundamentally determines the accuracy of the RP modeling.

Contents

Mastars Industries CO., LTD

Email: marketing@mastars.com

Tel: +86 755-88210689

Fax: +86 755-8821 0685

Add: Building 6,Blue Sky Industrial Park, Ditang Road, Shajing Town, Shenzhen City, Guangdong, China