As a special production process, Metal Injection Molding (MIM) has its unique advantages and characteristics. Mastars will use MIM process in rapid prototyping services and mass production service, so we first understand it.

What is Metal Injection Molding?

A metalworking process known as metal injection molding (MIM) involves mixing finely-powdered metal with binder material. Then, injection molding is used to shape it and solidify it.

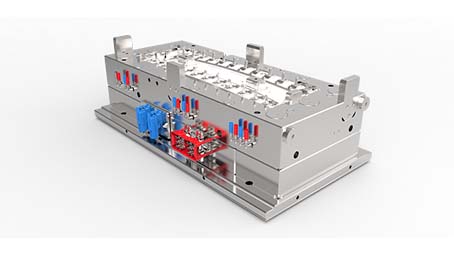

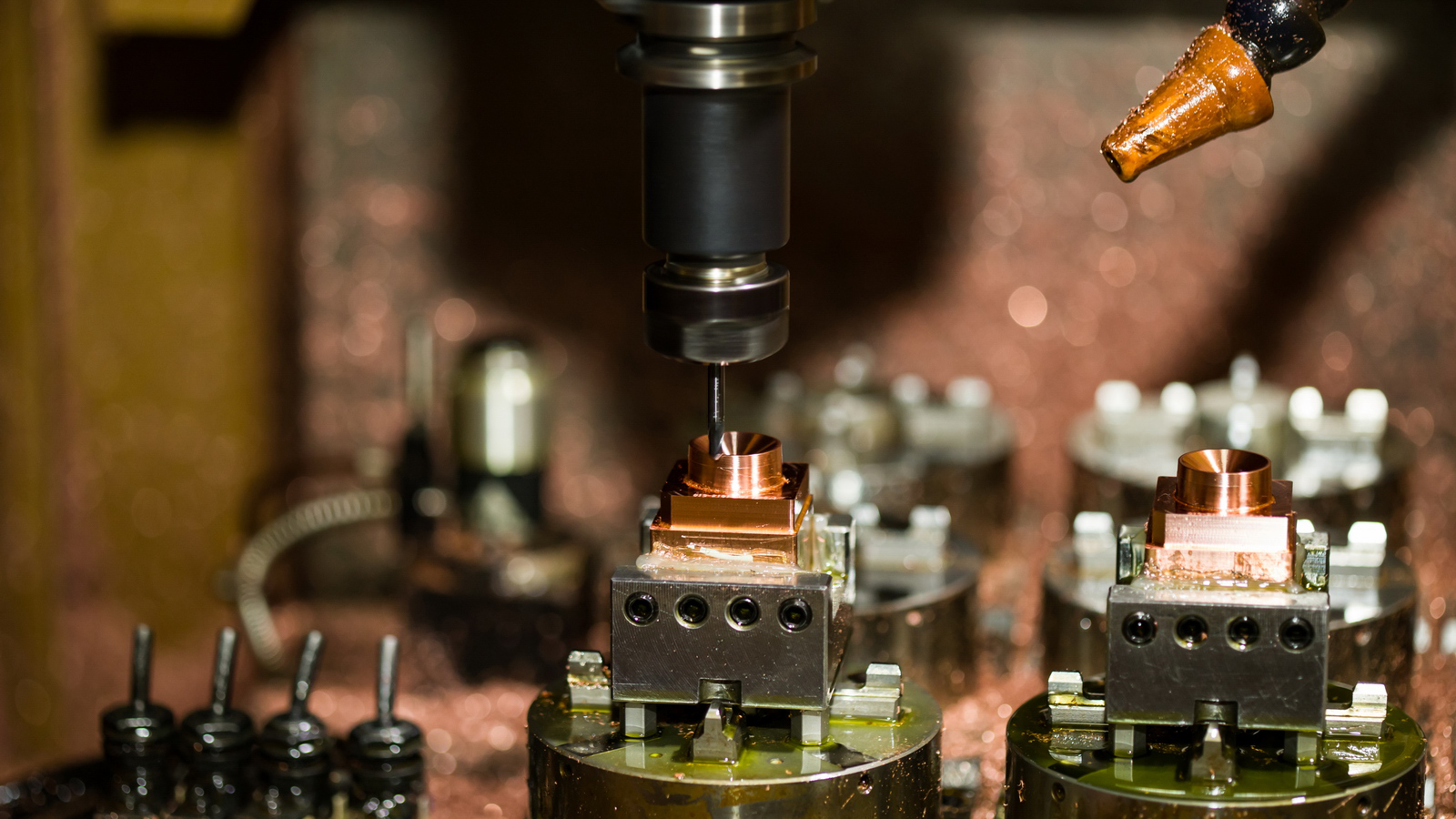

Metal Injection Molding Process

1.Preparing the feedstock

2.

Injection molding

3.Binder removal (Debinding)

4.Sintering

5.Finishing

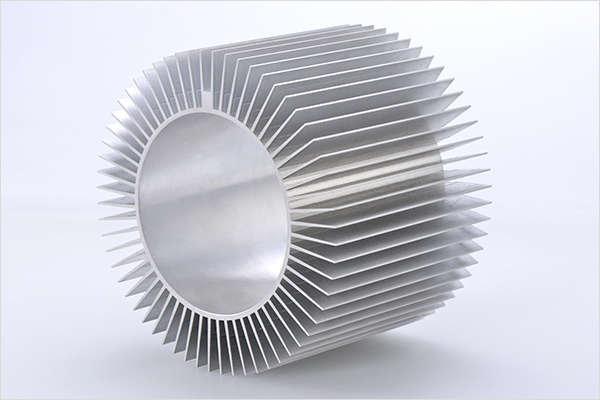

Commonly Used Metals for Metal Injection Molding

1.Low alloy steels

2.Stainless steels

3.High-speed steels

4.Irons

5.Cobalt alloys

6.Copper alloys

7.Nickel alloys

8.Tungsten alloys

9.Titanium alloys

Advantages of Metal Injection Molding

1.Geometries complexities

2.Material utilization efficiency

3.Producing near net shaped components results in less material waste, making this a greener technology

4.Reproducibility

5.Superior mechanical properties

6.Provide customized solutions with specially formulated materials for each component/application

7.MPP is suitable for brazing and joining a variety of components for a complete assembly solution

Applications of Metal Injection Molding

With the metal injection molding process, we are able to produce numerous materials, including stainless steels, low-alloy steels, and stool steels, that solve performance problems in areas such as medical devices, military and defense, sporting goods, industrial, oil and gas, and aerospace.

Mastars:

Mastars is a prototype company in China. We employ proven prototype technologies(

rapid CNC machining,

rapid sheet metal prototyping,

vacuum casting prototyping,

3D printing prototyping etc.), to take new concept or design and bring it to life, develop and evaluate new products quickly, economically and with less risk. With lesson learn from prototyping, we provide considered and proactive tooling design/build and mass production processing, from injection molding, die casting, CNC machining to final assembly as full one-stop solution.

Mastars Industries CO., LTD

www.mastars.com

Email: marketing@mastars.com

Tel: +86 755-88210690

Mobile: +86 181 0029 4997

Add: Building 6,Blue Sky Industrial Park, Ditang Road, Shajing Town, Shenzhen City, Guangdong, China