Evonik is launching three new INFINAM® photosensitive resin products for industrial-grade applications in 3D printing to expand the portfolio of photosensitive resins for common curing 3D printing processes, such as SLA or DLP, launched last year. In less than two years, Evonik has developed seven new photopolymer formulations, further enriching the diversity of material options for additive manufacturing.

The range of photosensitive resins continues to expand

INFINAM® RG 2000 L is a photosensitive resin for the optical industry. This clear liquid formulation cures quickly and is easy to process. The low yellowing index, even after prolonged UV exposure, makes this high-performance material suitable not only for 3D printed spectacle frames but also for microfluidic reactors, transparent high-end prototypes for observing the inner workings of complex components. Thanks to its excellent light transmission, INFINAM® RG 2000 L can also be used for lenses, light guides, lampshades and many other applications.

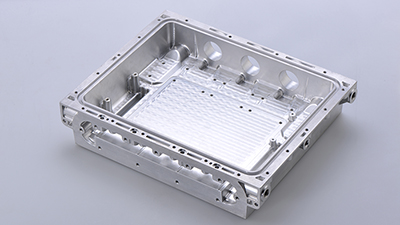

Developed specifically for DLP printers, INFINAM® RG 7100 L allows the production of components with excellent isotropy and low water absorption. Its mechanical properties are comparable to those of ABS materials and the formulation can be used in industrial printers. INFINAM® RG 7100 L can also be used in applications such as drones, fasteners and automotive parts where high ductility and impact strength are required. The printed parts can be machined and maintain good fracture resistance even under highly stressful conditions.

INFINAM® TI 5400 L has been developed with a focus on product applications for the fast-growing market of limited edition design toys that meet the needs of relevant customers - especially in Asia. This white material is a PVC-like resin that is well suited to producing items with rich detail and excellent surface quality, virtually indistinguishable from similar injection moulded parts. This fully cured material combines excellent impact strength and high elongation at break with long-lasting thermomechanical properties.

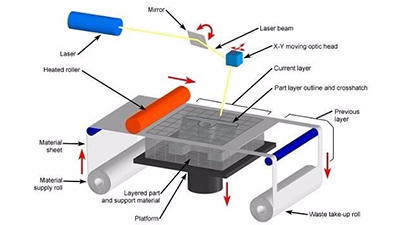

Driving 3D printing adoption at scale through innovation

Additive manufacturing is one of Evonik's six growth areas for innovation," says Lutz Mindach, Head of Research, Development and Innovation at Evonik Additive Manufacturing. We are investing above average in developing new formulations or further developing existing products. A broad selection of materials is the basis for the development of 3D printing into a scale-level industrial manufacturing technology."

Evonik's innovative growth area for additive manufacturing brings together the Group's in-house expertise in 3D printing technology and focuses on the development and production of new high-performance polymer materials for all major 3D printing technologies. To this end, Evonik has created the INFINAM® brand in particular and continues to promote the widespread use of industrial 3D printing production technologies across the entire value chain.