Mold Manufacturing - Mastars specializes in producing plastic products. It is an injection mold manufacturer integrating mold manufacturing, injection molding, oil injection, silk screen printing, etc

What are common injection moulded medical products?

Medical device products come in a wide range of shapes, sizes and costs. Some of the lower cost products can be plastic instruments, syringes, disposable gloves etc. and other disposable products used in the hospital environment. You may find that plastic products have replaced many of the glass products of the past, as the plastic available is cheaper and easier to recycle after use.

With higher costs planned, high performance resins and polymers are being used in pharmaceutical grade plastics. These specialised plastics are suitable for ingestion or implantation and can provide a means of controlling the release of drugs. These are often referred to as bioresorbable materials and they can remain in the body without harm. They can stimulate the growth of bone and tissue or be used in dissolvable vascular scaffolds, making them an exciting new opportunity for the plastics industry. Another advantage of polymers in the device sector is that they can reduce the weight of handheld medical devices, improve the functionality of the devices used and reduce production costs.

What common plastics are used in medical grade products?

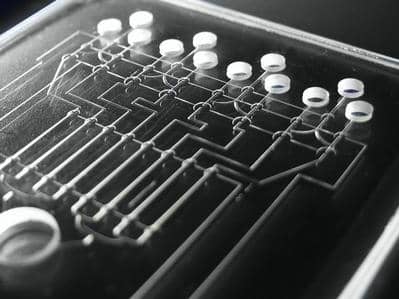

A common material used for medical devices is polystyrene. It is a colourless plastic that is hard and virtually inflexible. Some products use its transparency, while others mix pigments into the resin mix to provide colour variation. One of its properties is the low cost of the base material. In addition to simple and lightweight products such as tableware, it is ideal for hard but lightweight products such as petri dishes, flasks and pipettes. It is not recommended for long-term use in steam or autoclaves involving high temperatures.

Polyetheretherketone (PEEK) is a high temperature resistant thermoplastic that will not degrade in extremely hot, organic or aqueous environments. For applications requiring good abrasion resistance, the ability to survive in dielectric environments, not fluctuate in volume when subjected to heat and perform well in environments prone to radiation

Polypropylene is another common material used for medical products. It can be used for products that require autoclaves and can therefore withstand high temperatures for long periods of time. It can also survive radiation treatment and keep samples stable without risk of degradation.

Polyethylene's low heat resistance makes it an undesirable choice for heating environments with little variation in shape and size. It is commonly used in containers, breathable patches and packaging films.

Polycarbonate is also an injection moulded plastic and is often found in medical devices. It is a robust material that can withstand high impact, provides a transparent translucent material, is stable in hot and cold conditions, is resistant to UV degradation and is flame retardant. Temperature stability and strength make it ideal for high-pressure syringes, centrifugal force separators, blood filter housings and other products.