The mascot of the Beijing Winter Olympics, "Bing Dwen Dwen", has become very popular. The simple, honest and lovely mascot Bing Dwen Dwen has become a veritable top of the Winter Olympics, resulting in a difficult situation to get one piece. Bing Dwen Dwen requires complex processes to generate, the most important of which is the production of precision molds, and the 3D contour of the "Bing Dwen Dwen" mold core is complex, and its manufacturing requires CNC five-axis linkage machining. Mastars has a precision plastic mold and injection molding team with rich theoretical and practical experience. The key members have more than 20 years of mold industry experience, and have a number of core technologies and patents in complex mold structure, mold flow analysis, conformal cooling technology, processing thermal deformation management. The products are exported to all over the world, and we have a strong ability to design and manufacture precision molds.

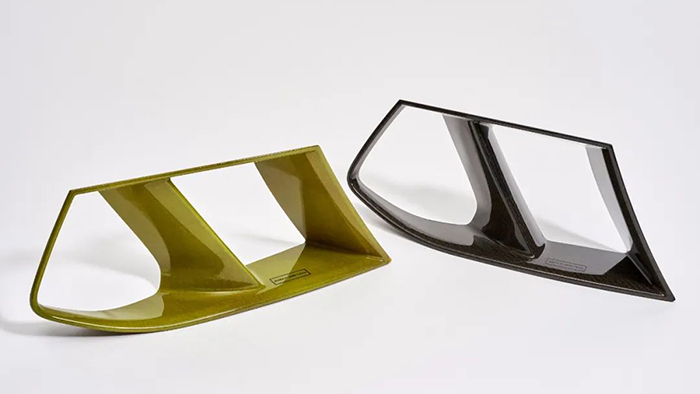

"Bing Dwen Dwen" has extremely high requirements on the transparency of the silica gel shell. This material has a good feel and can reach environmental protection food grade. The overall production process of the silica gel shell is: 3D modeling and processing molds, rubber refining forming and thermal transfer printing.

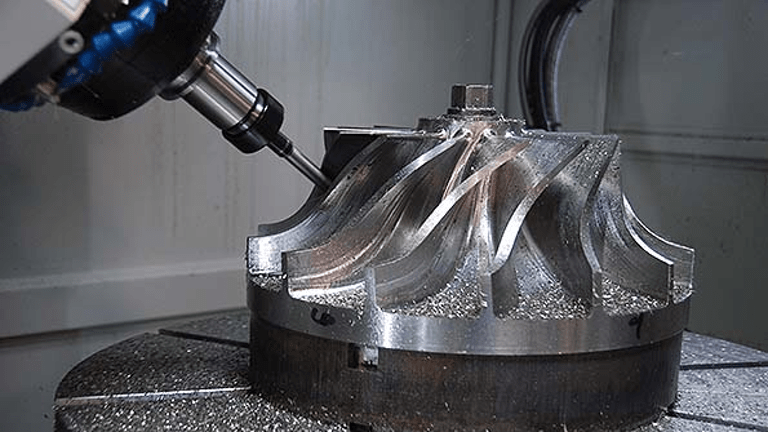

The large-scale production of silica gel shells is naturally inseparable from sophisticated molds, and the 3D surface of the "Bing Dwen Dwen" mold core is complex. Its manufacturing requires CNC five-axis linkage processing, and the mold surface needs high-gloss polishing treatment.

The production process of "Bing Dwen Dwen" silica gel shell is a kind of compression molding. Compression molding can optionally be processed by solid or liquid production process.

The raw material of the solid silica gel molding process is solid, which is cut into suitable size and thickness after mixing by the mixer and then put into the mold, and molded at a certain temperature of the pressure molding machine. The raw material of the liquid silica gel molding process is injection molding liquid silicone rubber, and the vulcanization equipment is an injection molding machine.

In order to achieve the large-scale production of Bing Dwen Dwen silica gel shell, it is necessary to make an accurate mold, clean the mold, polish it, and then put the silica gel on the mold and send it to the machine for shaping. The process of demolding should be very delicate, and there should be no damage. After completion, the Olympic rings and rainbow strips should be integrated into the product.

" Bing Dwen Dwen" silica gel shell is larger in size, which is different from other small products that can be produced dozens of products in one mold. A set of " Bing Dwen Dwen" mold can only produce two silica gel shells at a time. Two sets of molds can only make 800-1000 shells a day at most. In this way, in order to meet the market demand, it is necessary to increase the number of molds from two to dozens, and at the same time speed up the production of molds.

The most difficult process to make a silica gel shell is the "ice ribbon" on the case. Because the "ice ribbon" is surrounded by five colors, and the printing is generally carried out on a flat surface, it is difficult to accurately print the ice ribbon to the corresponding position. After continuous polishing, a relatively mature thermal transfer technology is used.

It is understood that it takes about half a day to make hundreds of Bing Dwen Dwen shells and print the patterns. It is then sent to the plush factory for assembly and then to the retailer. It takes at least 2 days for a Bing Dwen Dwen to go from production to the final consumer.

Mastars

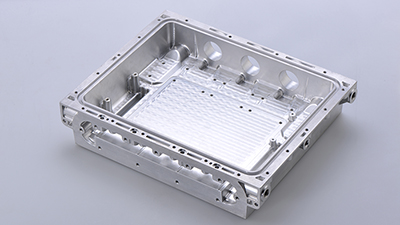

Mastars is a company that designs, develops and produces precision plastic parts. The products involve in automotive, communication electronics, medical and personal care, medical consumables, smart home, semiconductor, new energy and other fields, focusing on the development of smart medical, artificial intelligence, IOT and other fields, providing customers with customized manufacturing services of high precision plastic parts.