Mastars is a plastic and metal parts manufacturer offering 3d printing services (SLS, SLA and SLM), rapid CNC machining, plastic tooling, and services for the electronics, electrical, automotive, office supply, cosmetics, medical device, 3C, and other industries.

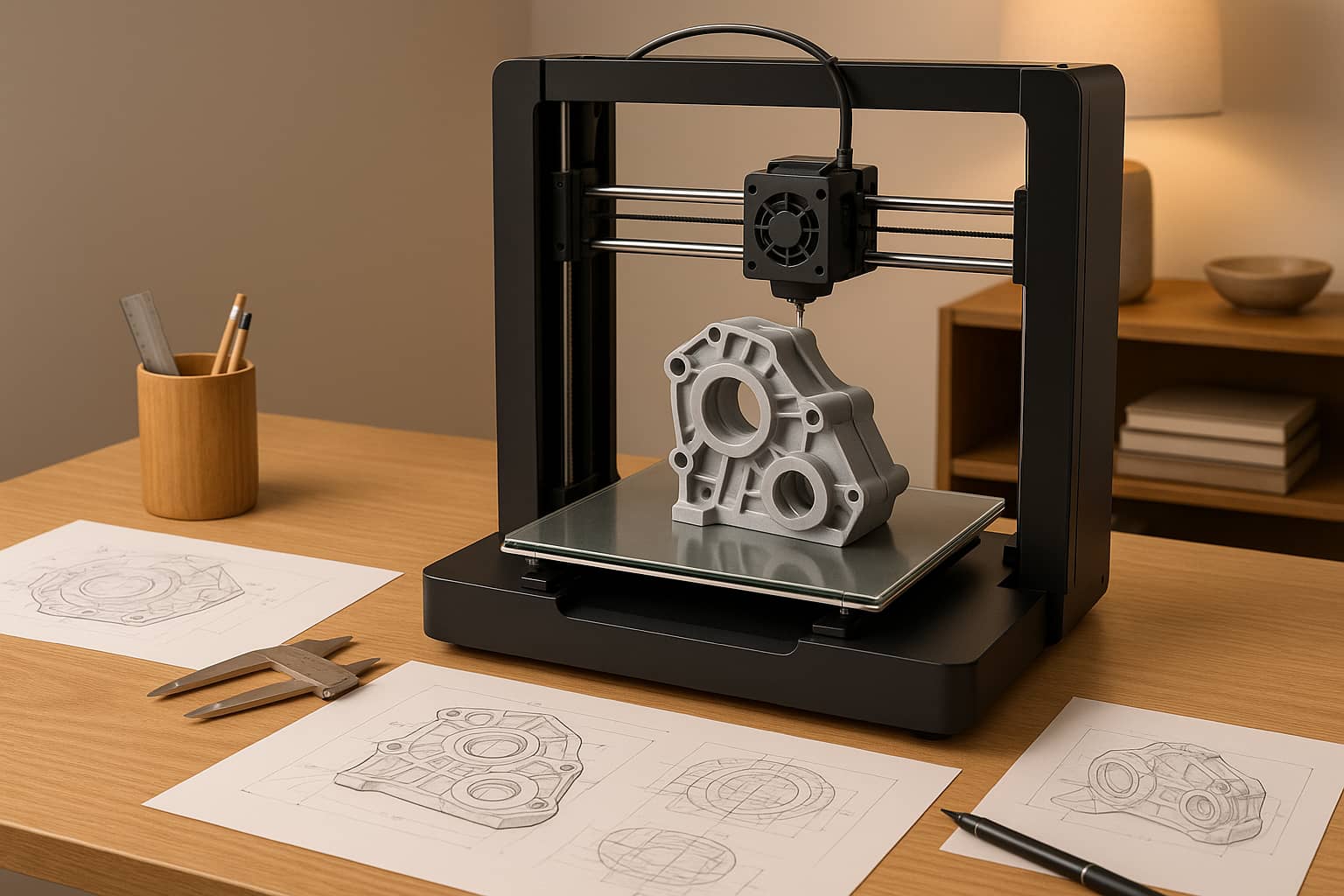

Additive manufacturing technology can highlight its advantages in shaping complex geometries: any shape using 3D CAD programs can be produced using innovative laser sintering technology. There are no restrictions, even for the production of hollow structures. This is because the material is applied only in the desired position.

Additive manufacturing gives developers maximum freedom of construction. The overall size of the external geometry of the component is almost the only factor that affects the cost. That is, its complexity is almost independent of the cost of production. Because less material is consumed, significant cost reductions are often possible.

The complexity of the component is no longer limited by the manufacturing process, but only by the required functionality and product design. In general: the more complex the geometry of the component, the higher the practical value of additive manufacturing.

A typical application in the medical field is the production of human acetabular cups with high stability and a complex surface structure that facilitates osseointegration, in other words, the organic fusion of bone tissue with the surface of the bone implant. With additive manufacturing technology, it is possible to tailor the part to the needs of each patient using titanium alloys. It is almost impossible to produce such a complex surface structure using conventional manufacturing methods.

One thing is certain: the acetabular cup consists of a fixed profile that ensures optimal stability and a carefully designed porous structure that effectively promotes osseointegration. Both profiles are realized in one production session. Numerous pores of different sizes help to fix the implant: the larger pores are suitable for transmitting pressure, while the smaller pores help with initial fixation. Another unique feature of additive manufacturing: the structure, surface roughness and pore size of the implant can be customized for each patient.